Backflow Preventer Testing

What is backflow preventer testing and how is a backflow preventer tested?

Backflow is always a problem. When contaminated water streams back into the potable water supply, it's a potential health crisis, and might be quite serious. And if a water main bursts or the fire department needs to open a number of hydrants simultaneously, the chance for flow reversal goes up. Even freezing pipes can change the pressure in water hoses, again causing a backflow crisis. The backflow preventer is the only device standing between clean water and cross-contamination.

Of course, once a backflow preventer device is in place, it needs to be maintained. And that's where a trained and certified backflow preventer testing expert comes in. An annual maintenance check can mean the difference between a sudden and highly unpleasant cross-contamination event and simple smooth sailing for your business location or home. What, then, does the tester do?

Types of Backflow Prevention Devices

Although there are many varieties of backflow preventers, the equipment comes in two basic options.

Although there are many varieties of backflow preventers, the equipment comes in two basic options.

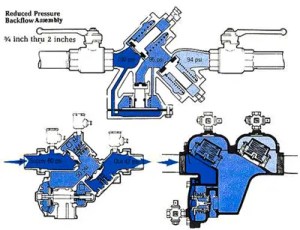

One is a reduced pressure principle device. This device contains two independently-acting approved check valves, as well as a hydraulically operated, mechanically independent differential pressure relief valve. This valve is located between the two check valves. During a backflow condition, this device will discharge a large volume of water, depending upon the size of the assembly. It is essentially designed to prevent backflow caused by backpressure or backsiphonage and may be installed on either low or high hazard connections.

The other is a set of double check valves. This assembly also works to prevent back pressure and back siphonage. However, it is not used for high hazard applications, but is installed for lawn irrigation, fire sprinkle and combi-boiler systems.

Double check valves are assembled in series. If one check valve is jammed wide open, the other will still function. And the closure of one valve tends to reduce the pressure differential across the other. This system allows a more reliable seal and can avoid even minor leakage.

No matter which system your plumbing has, you need a professional to determine the pressure within your plumbing lines. He can advise you if you have any problems that could lead to backflow issues.

How the Test Works

To test your backflow preventer, a backflow certified plumber will turn off the downstream shut-off valve and wait a few minutes. After that, he’ll test the pressure in the system by hooking up test kit hoses. Basically, the plumber is basically looking for areas where the pressure isn't what it should be. You'll need a plumber certified in backflow testing, rather than a regular licensed plumber. A certified plumber has taken hands-on courses and passed an examination to qualify for his certification.

If the tester finds that your system is in danger of causing cross-contamination, he can repair your existing system, or, if necessary, install something new.

Ready to get your backflow preventer system tested? We service all of Northern Colorado (excluding Denver), and Southern Wyoming. Contact us to set up an appointment.